Spatial dimensions that define the benchmark

Innovation and precision unfold in syntechnics' spacious halls, which cover more than 3,000 square meters. Two halls, one dedicated to production, the other designed as a warehouse, form the backbone of our work. Here, spaciousness and functional design merge to create an environment in which efficiency and precision take center stage.

CNC technology: where precision becomes art

Three CNC machines, each state of the art, define the core of our manufacturing strength. With a machining area of up to 15,500 x 6,200 x 3,000 mm³, we set new standards in the production of large and complex projects. This is where technical precision becomes a tangible reality.

Tempering and painting areas: Innovation in every detail

Our specialized tempering and painting areas are true examples of advanced technology. They allow the processing of workpieces with maximum dimensions of 17,000 x 5,000 x 4,500 mm³ and offer the flexibility to reach temperatures of up to 200°. In these areas, solutions are created that are unparalleled in their precision and adaptability.

CAD/CAM systems: Design meets precision

The integration of CAD/CAM systems such as Catia and Rhinoceros into our development process is a commitment to customized excellence. These systems are at the heart of our ability to implement individual customer requirements with the utmost precision and creativity.

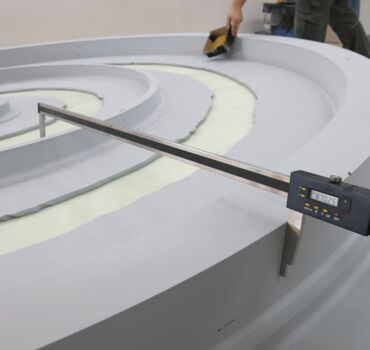

Measuring systems: quality that can be measured

Our commitment to quality is reflected in the use of advanced measurement systems. Technologies such as photogrammetry, strip projectors and laser scanners ensure that every product that leaves our factory is a guarantee of quality and precision.