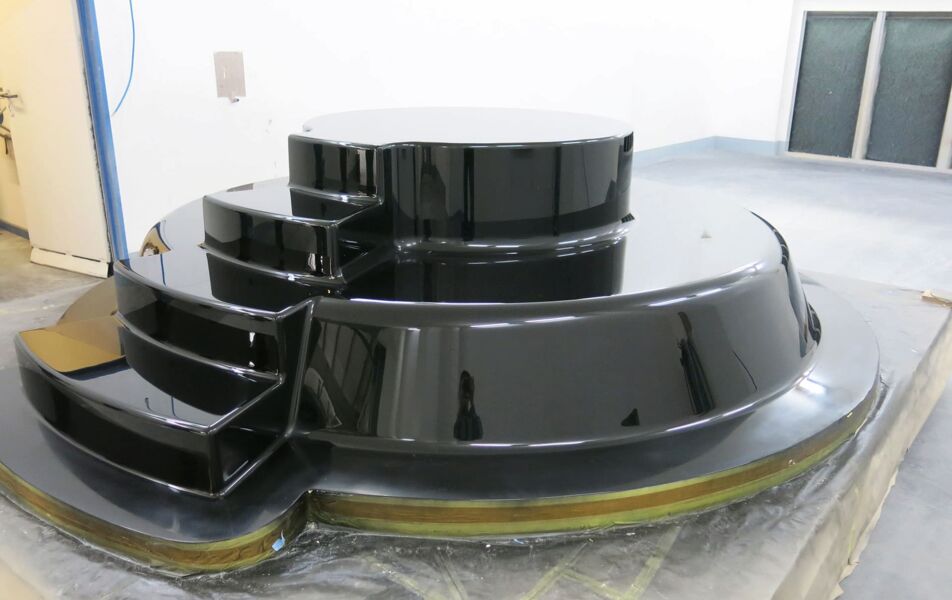

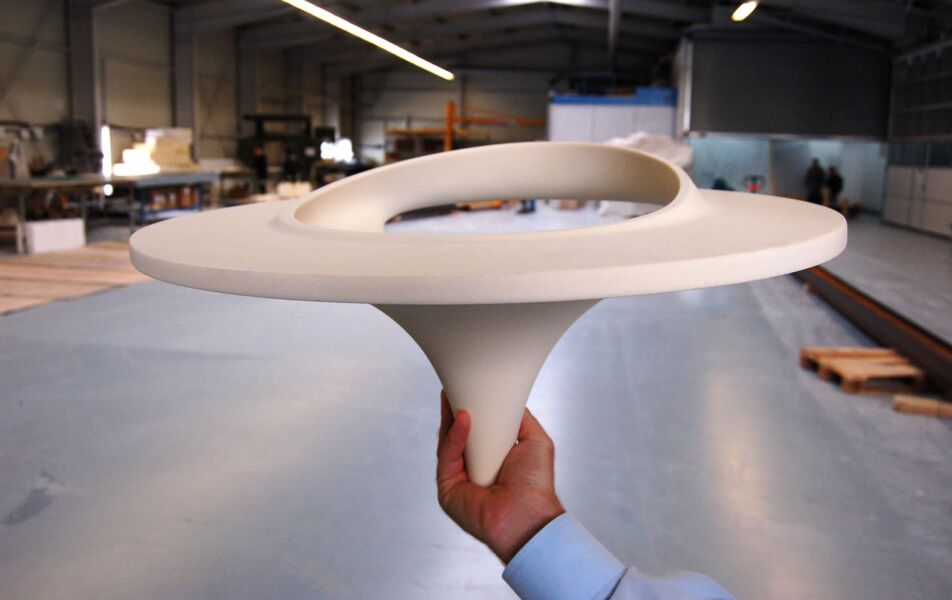

Molding & tooling

Attention to detail

Precision and quality are crucial in mold and tool making. Our expertise enables us to produce high-quality molds and tools that meet the highest requirements.

Molds & tools for your manufacturing

Forming tools are mainly used in the plastics processing industry, but also in concrete construction and foundries. For concrete casting, we produce negative molds with different surface qualities and durability.

High-precision manufacturing

Individual solutions

State-of-the-art technologies

Longstanding experience

Molding & Tooling services

Solutions & products

syntechnics GmbH

Ringstraße 16

23758 Oldenburg in Holstein

Germany