CNC machining

Precision meets quality

Using the latest CNC technology, we offer custom solutions for your specific needs.

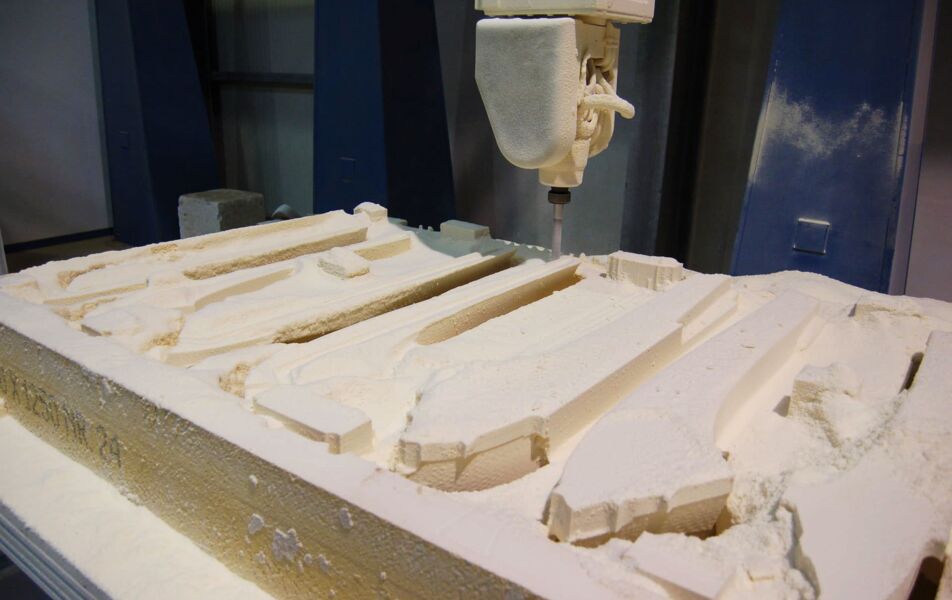

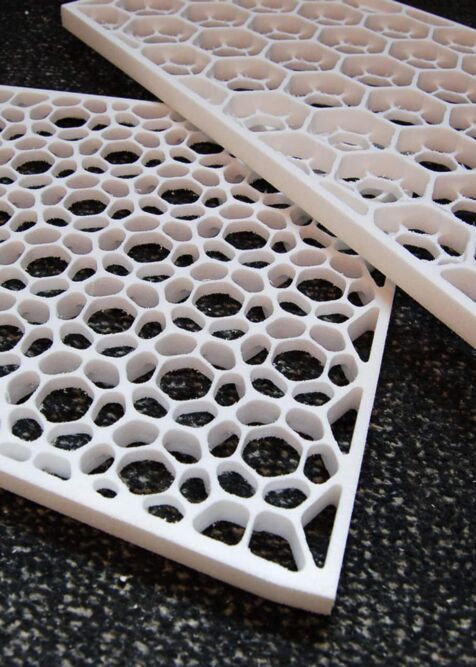

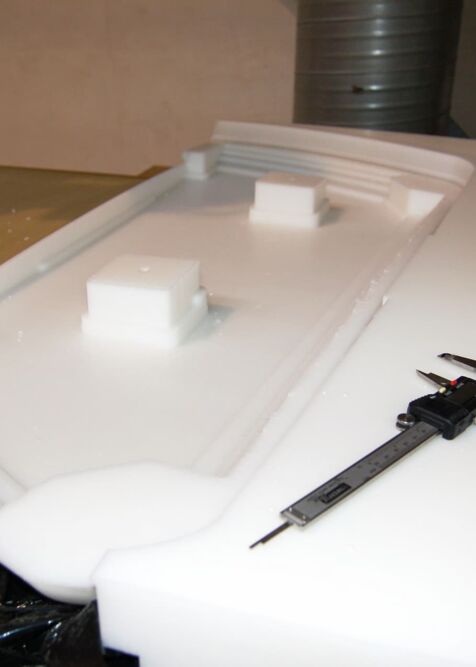

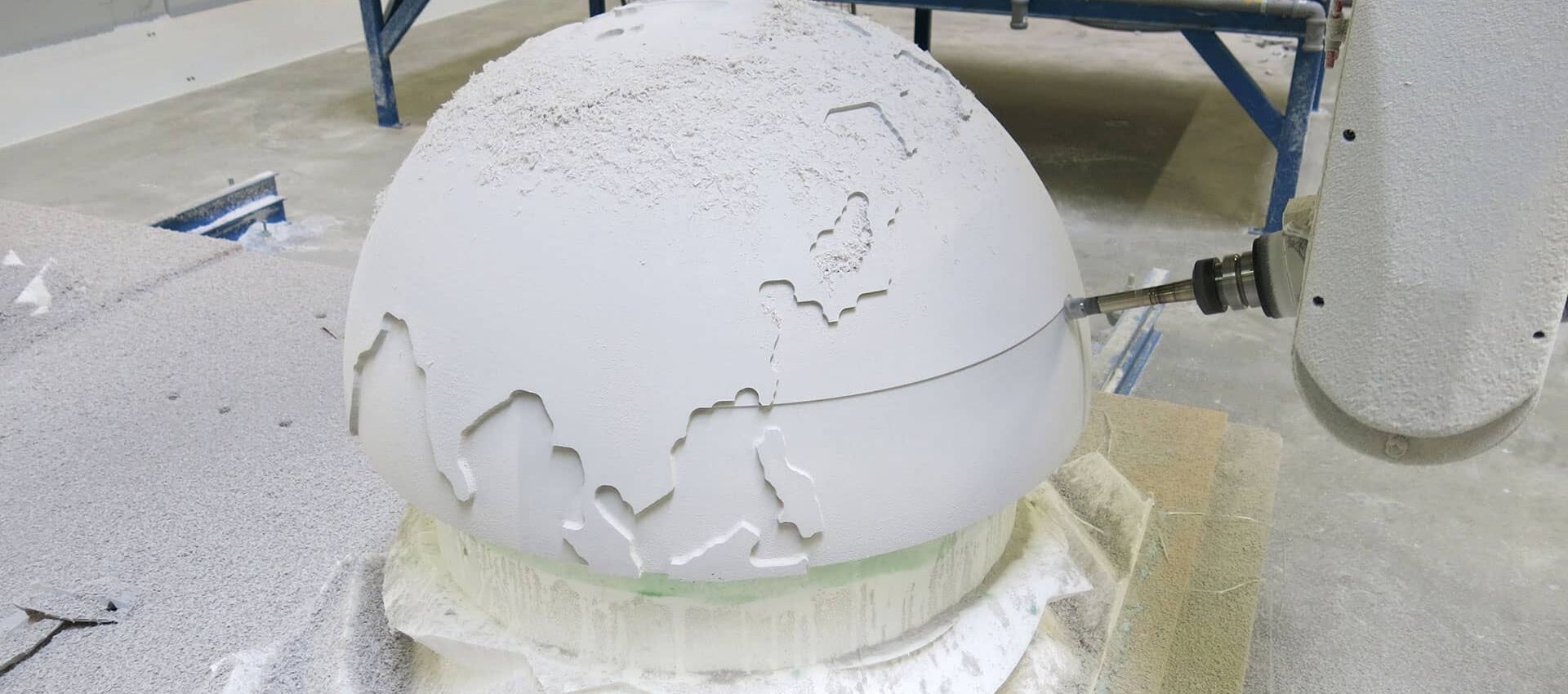

Milling

Our CNC machining technology represents the highest precision and quality. We rely on state-of-the-art machines and techniques to meet your needs.

High precision

manufacturing

Custom solutions

Modern technology

Experience and

know-how

CNC services

Materials & components

syntechnics GmbH

Ringstraße 16

23758 Oldenburg in Holstein

Germany