References

Our success stories

Discover the multi-faceted world of our projects and find out how we successfully implement unique and challenging projects as a full-service provider.

SUCCESSFULLY COMPLETED PROJECTS

Our references

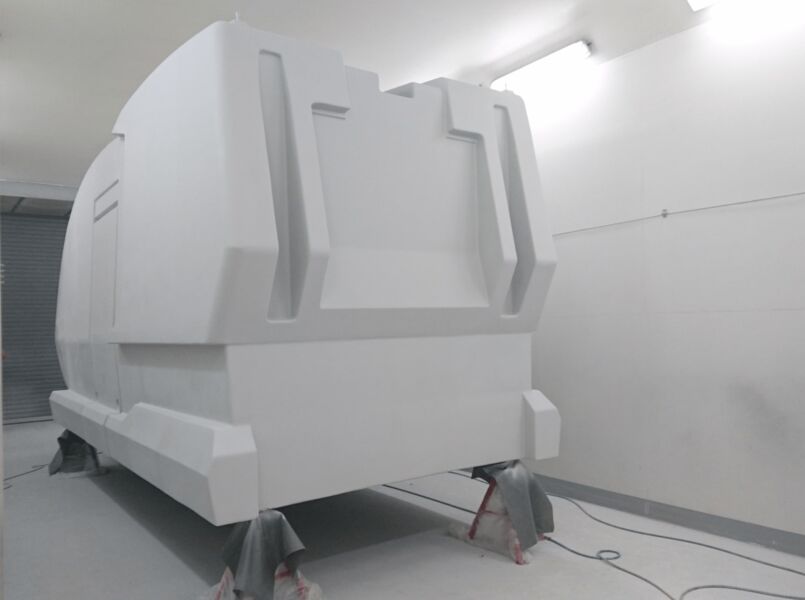

Star Trek spaceship for the Netflix trade fair appearance at Ifa

Material |

Industry / customer |

| Composite / GRP / steel | Trade fair construction / Netflix |

Description:

To promote the launch of the new Star Trek series at the Ifa, that was Netflix's goal and our task. We developed a design, had it approved by the copyright holder in the USA, and after only 7 weeks of production, the spaceship was loaded and transported to Berlin. Inside the spaceship, visitors were able to have a Star Trek character projected live onto their own face ("face mapping").

Delivery included:

Design, concept development and realization, including construction and painting, transportation and assembly at the fairground.

Multimedia travel kiosk for Lufthansa

Material |

Industry / customer |

| Steel | Advertising / Lufthansa |

Description:

Awaken wanderlust. That is the declared goal of this advertising idea, which takes people out into the wide world via livestream. The concept was developed in close cooperation with Amptown System Company (ASC), who also developed and implemented the media concept. Eight weeks were available for the full production. The travel kiosk was first used in Düsseldorf, then at the ITB in Berlin and in other major European cities.

Delivery included:

Design, engineering, design, development and implementation including construction and painting. We would like to thank our customer for providing the pictures.

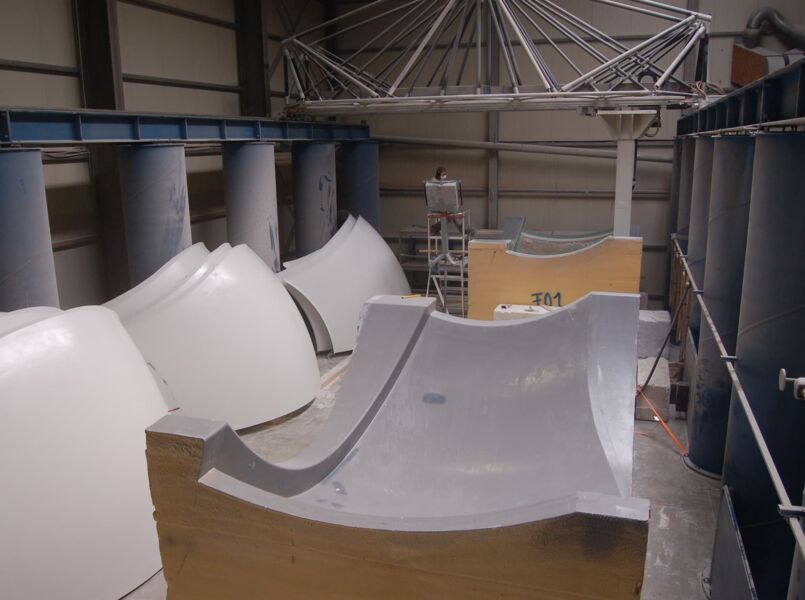

Construction of exhibition pavilions and aircraft models for the Paris Air Show

Material |

Industry |

| Carbon fiber and glass fiber reinforced plastic (GRP, CFRP) | Trade fair construction |

Description:

At the exhibition stand of a renowned aircraft manufacturer, the 4 pavilions formed the central exhibition elements of the trade fair concept. The aircraft models were used to present new transportation concepts. More than 200 square meters of GRP and the necessary molds were produced within only 7 weeks.

Delivery included:

Data validation and expansion, CNC molds, production of GRP and CFRP components, CNC trimming of components, pre-assembly, surface finishing and delivery to France.

Construction of two art sculptures for a Danish museum

Material |

Industry |

| Carbon/fiberglass-reinforced plastics (CFRP, GFRP) | Art |

Description:

Based on a 3D file from a renowned Danish artist, we have produced two sculptures in an elaborate, multi-stage manufacturing process. The supporting structure is made of CFRP. The tubes are made of steel and the foundations are cast according to our master models. The sculptures were FE calculated by us and are vandal-proof. We also handled the final assembly in front of the museum in Aarhus.

Delivery included:

Construction, design and dimensioning incl. proof of stability, fabrication, painting and assembly/installation.

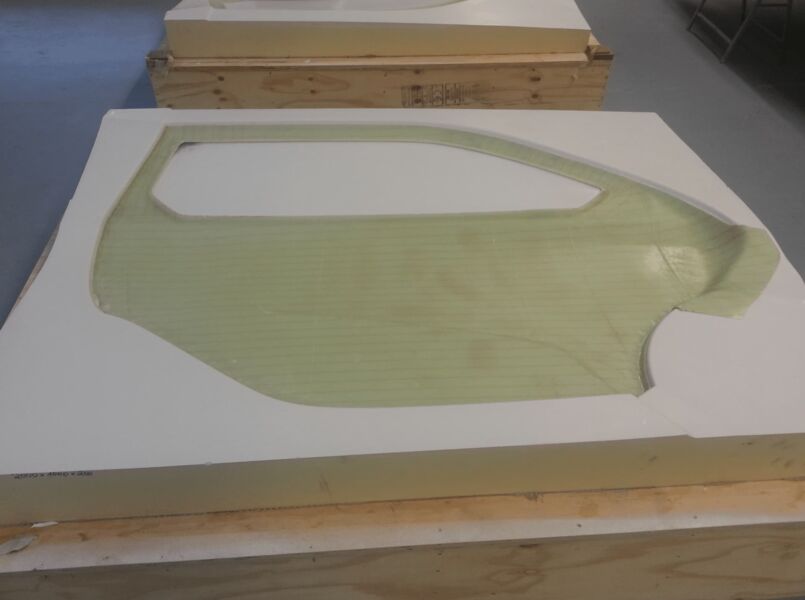

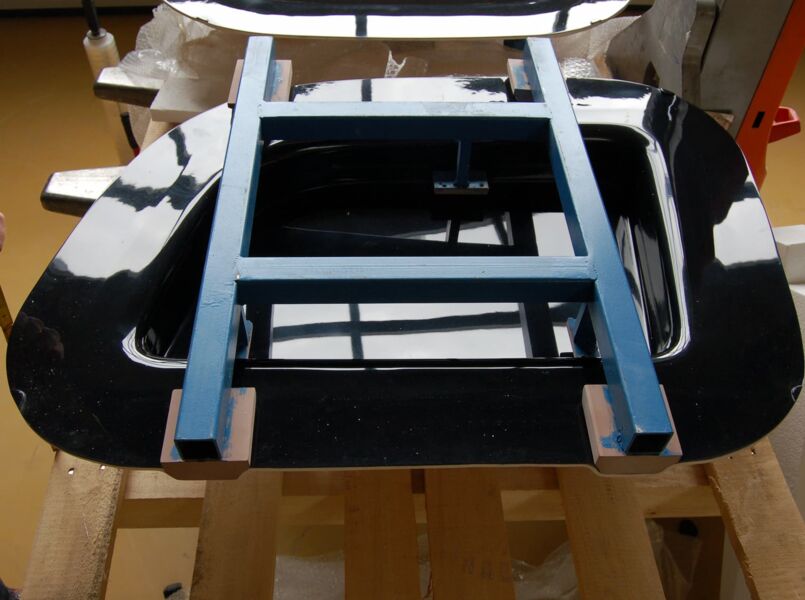

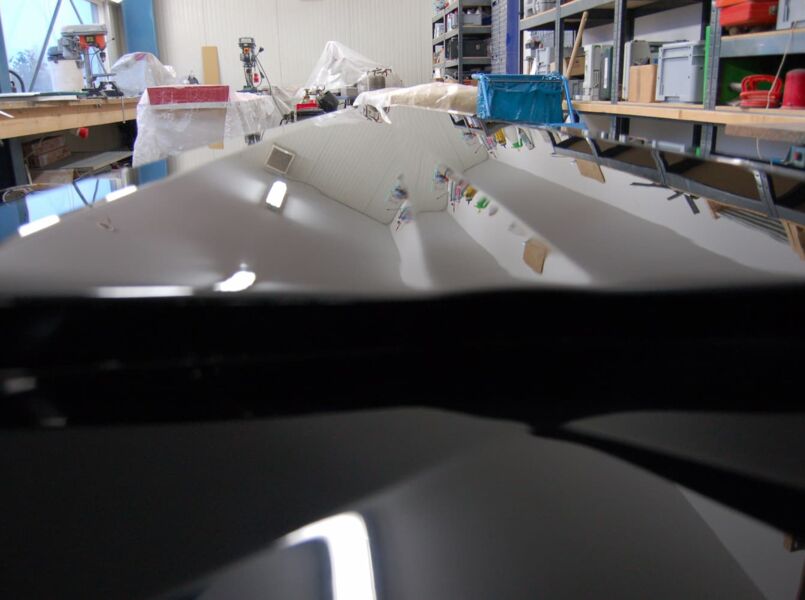

Complete vehicle paneling made of GRP for a newly developed electric vehicle

Material |

Industry |

| Glass fiber reinforced plastics (GRP) | Vehicle construction/automotive |

Description:

This new development is characterized by innovative detail solutions. A special feature of this electric vehicle is the ability to rotate all four wheels up to 90°, making it possible to turn on the spot and drive sideways.

Delivery included:

Based on our customer's 3D design data, we detailed the chassis design, derived the mold design, CNC milled the molds (direct moudling) and manufactured the GRP components in a vacuum infusion process. After assembly by our customer, we performed the final painting of the assembled parts.

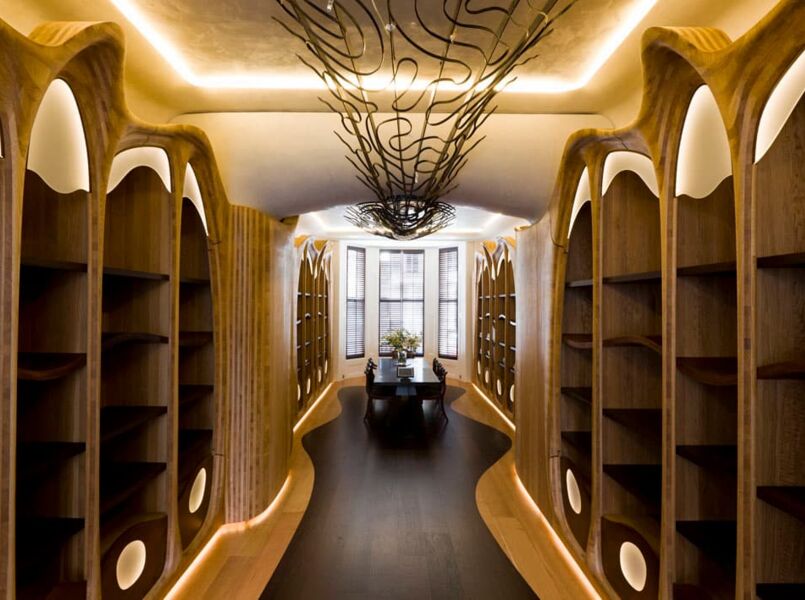

Oak Wood Library for a Private Villa

Material |

Industry |

| Solid oak wood | Exclusive interior designer and furniture maker |

Description:

In a private villa in London, this more than impressive library was created. The special frame consists of 27 oak wood fronts and ceiling elements with dimensions up to 3.20m in length and wood thicknesses of up to 400mm. In total, more than 40m³ of dried oak in A-grade were purchased, sorted, split, and glued layer by layer in a crisscross pattern. The actual design language emerged from subsequent CNC processing. The dimensions, weights, and features of the elements demanded special creativity in developing the clamping and mounting. Finally, the wood surfaces were finely sanded. Our client then only oiled the surfaces.

Delivery included:

Data adjustment, construction (CAD), raw part development and production, CNC processing of approx. 40 m³ oak wood, surface sanded, dimensions up to 3,200 x 1,650 x 400 mm

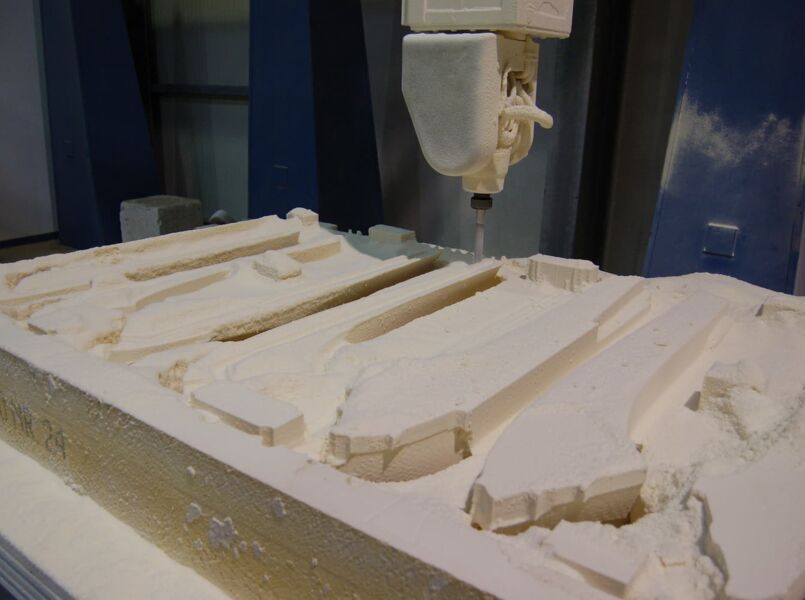

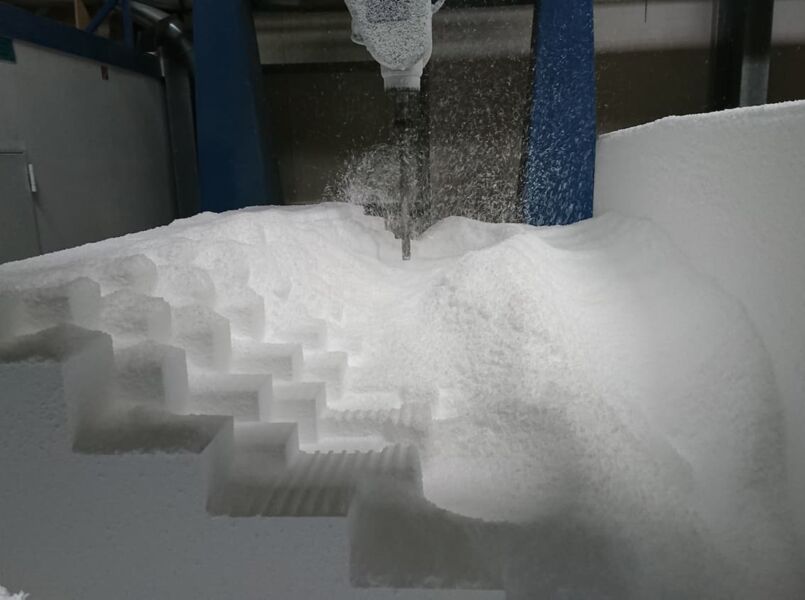

CNC milled concrete moulds for a truck test track

Material |

Industry |

| Rigid polystyrene foam (EPS) | Construction/commercial vehicles |

Description:

An innovative test centre has been built at the world's largest Mercedes-Benz truck plant in Wörth am Rhein. The centrepiece of the test centre is a 4km test track with a computer-calculated surface profile. The aim is to simulate the lifecycle of a truck on the road in the shortest possible time and to optimise components. The test track consists of precast concrete elements. We have produced the concrete moulds needed to make them. The total surface area is more than 18,000 m², which we delivered in less than 6 months. We had to process more than 4,000m³ of EPS to make the more than 5,000 individual parts. We were the single point of contact for both the client and our customer, both in terms of CAD design and project management of the many different moulded parts.

Delivery included:

Data validation, raw data merging, machine programming (CAM), CNC machining, complete logistics including on-site disposal.

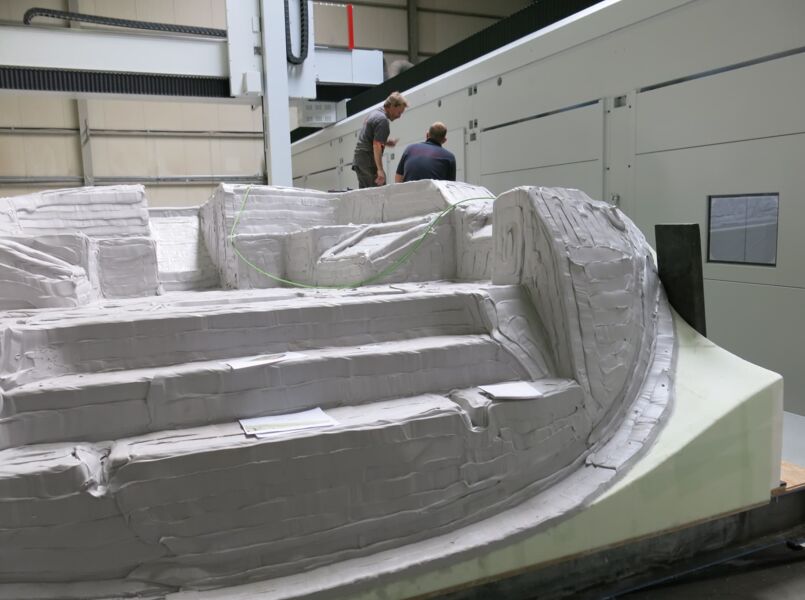

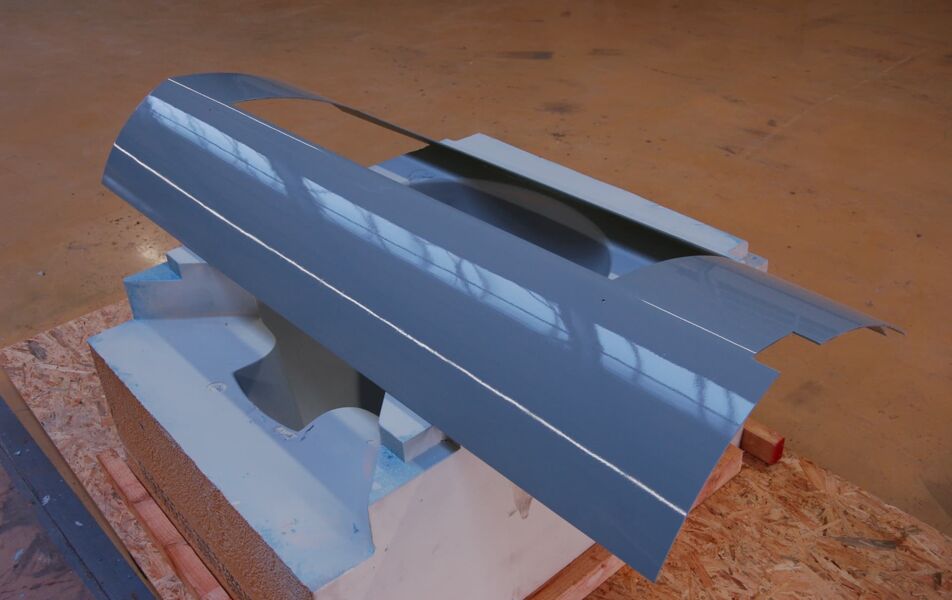

Original boat models for various new developments

Material |

Industry |

| Epoxy paste, high-gloss lacquered and polished | Boat building |

Description:

The serial production of modern GRP boats and yachts takes place in permanent GRP moulds. To produce these moulds, master models are required which are a 1:1 copy of the component. We produce master moulds for topsides, hulls, decks and many other components for various manufacturers including X-Yachts, HanseYachts, Bavaria and others. We have now supplied several hundred square metres of model surface and are highly regarded for our excellent surface quality.

Delivery included:

Data validation and enhancement, CNC modelling, high quality paint, suitable for our customers' polyester tooling systems.

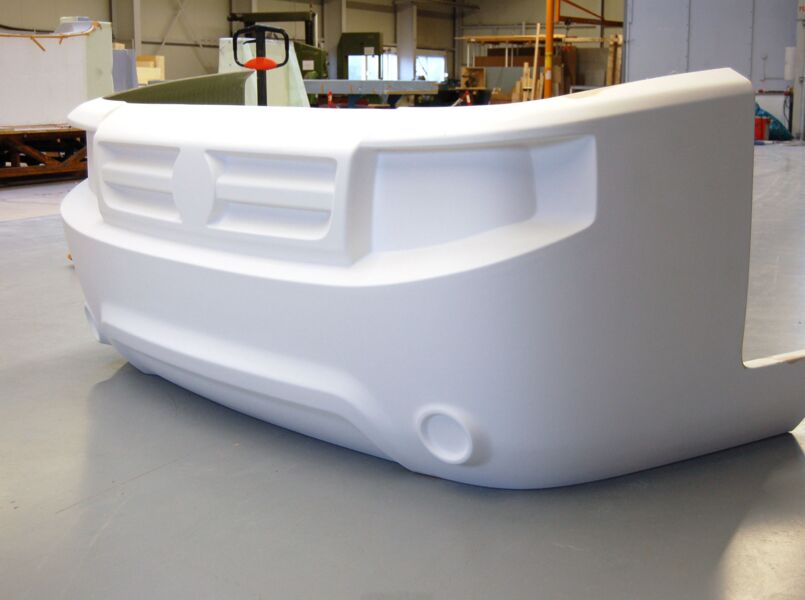

GRP Parts for Various Special Vehicles

Material |

Industry |

| GRP (epoxy, partially sandwich) | Special vehicle construction |

Description:

Our client builds special vehicles such as visitor trains for the Warsteiner Brewery and mobile bank branches for savings banks. The parts we manufacture include vehicle fronts, door panels, frame profiles, lighting surrounds, both in series and as custom-made items. Unlike the usual method, we produce the profiles not as polyester GRP but with epoxy resin using the vacuum infusion process. The client explicitly desires the higher strength and stiffness to optimize the statics of their structure. CNC milled sandwich cores are used to improve thermal insulation.

Delivery Included:

Design, CNC mold construction, production of GRP parts including CNC milled sandwich cores, and pre-finishing of surfaces.

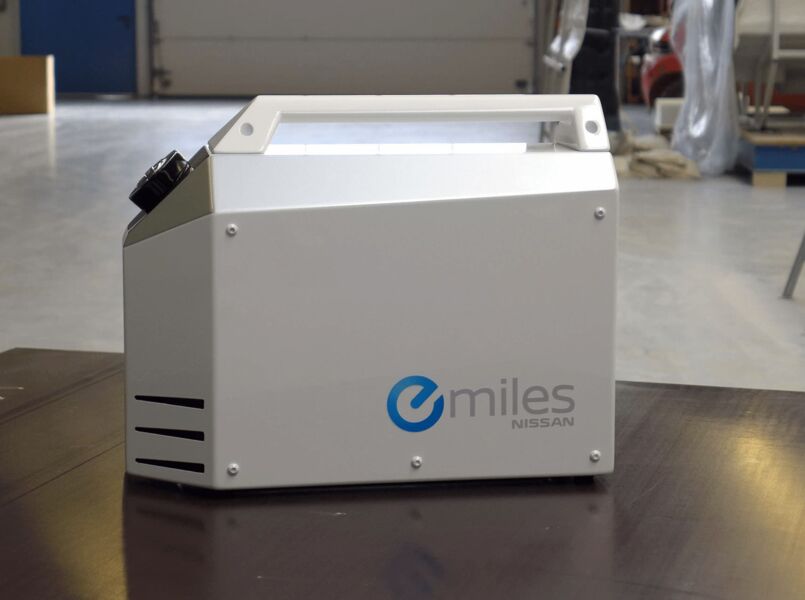

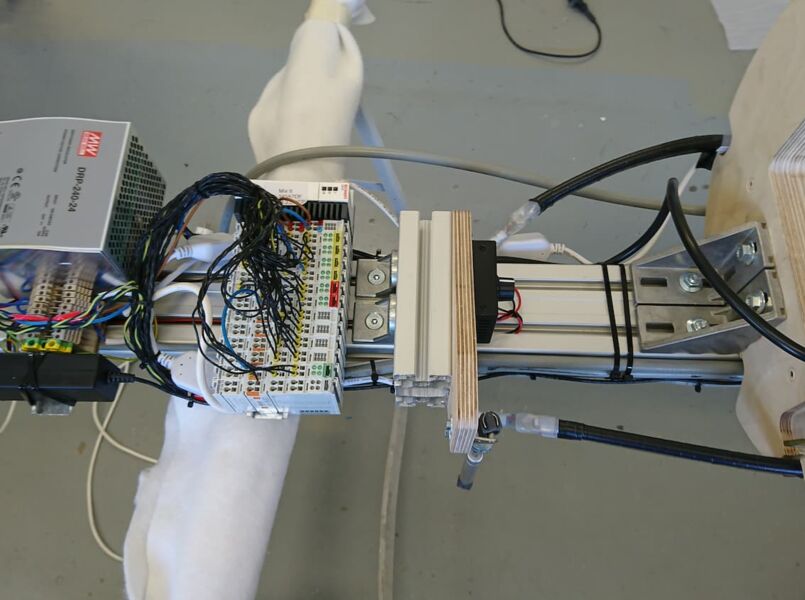

Battery reserve canister eMiles for the Nissan Leaf

Material |

Industry |

| CFRP/carbon, Li-Ion | Automotive |

Description:

In just 7 weeks, we transformed this idea into a functional prototype. From specification to the finished connection cable, we designed, constructed, and built the entire system. The project featured state-of-the-art high-performance batteries, reliable charging technology, and a high-strength, very lightweight carbon housing.

We thank our client for providing the pictures.

Delivery included:

Specification, layout, construction, and turnkey production

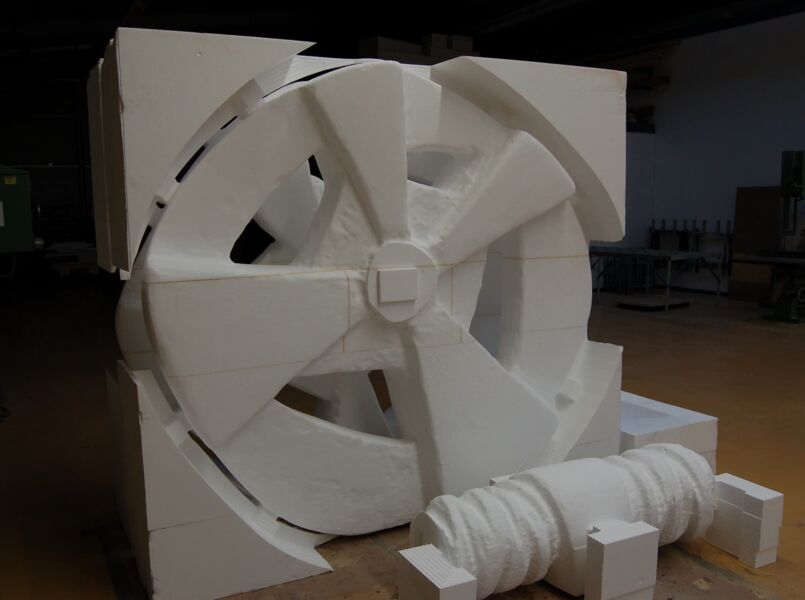

CNC model making for foundry models in wind power and boat building

Material |

Industry |

| Wood, EPS, model building paste | Foundry (wind power, boat building, etc.) |

Description:

For various applications, we have already produced a multitude of foundry models, including large models with dimensions of 5 x 5 x 3 m. The models are created on suitable substructures and receive a durable surface finish so that they can be used frequently as needed.

Delivery included:

Data validation, construction of gating systems, shrink scaling, machine programming, CNC model making, surface finish with coatings suitable for the sand casting process.

Interior and exterior parts for a sailing yacht

Material |

Industry |

| Fiberglass-reinforced plastics (GRP), non-flammable composite material | Yacht building/shipbuilding |

Description:

For this very large sailing yacht, we supplied all involved interior designers with components for both the interior and exterior. In total, we manufactured several hundred square meters. Some of the assembly on board was carried out by us.

Delivery included:

Data preparation, partial 3D construction, CNC mold construction, manufacturing of laminates, CNC trimming of components, installation of substructures, pre-assembly of assemblies, and surface finish

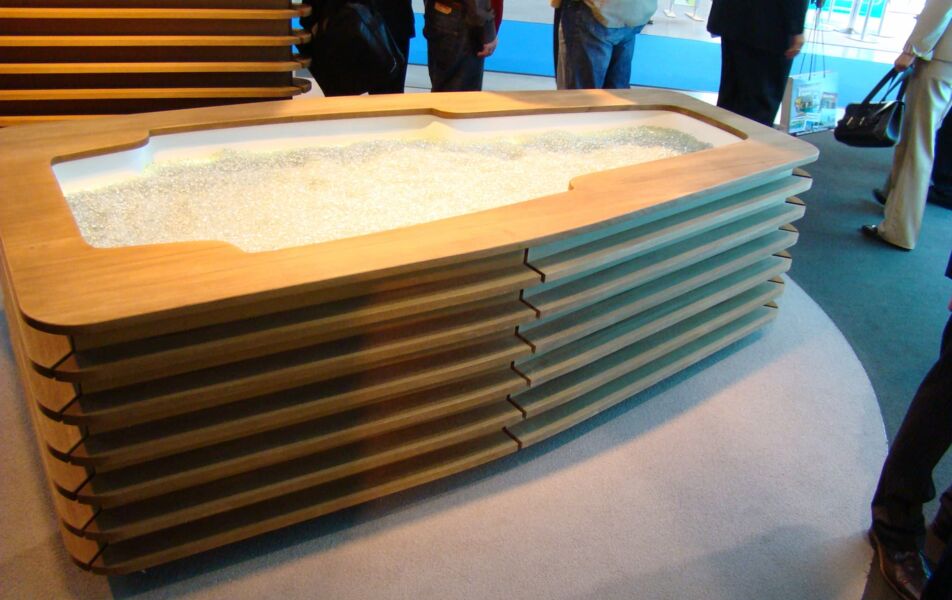

Pebble and glass chip loungers for the spa area of several hotels

Material |

Industry |

| Glass fiber reinforced epoxy plastic (GRP) | Wellness/spa, global market leader |

Description:

The wellness and spa areas of luxury hotels are highly valued. In addition to the usual equipment, hotel visitors expect high-quality and special facilities. Undoubtedly, loungers filled with pebbles and glass chips, heated, are particularly special and high-quality as delivered by us.

Delivery included:

Directly CNC-milled molds, two-part GRP execution, seamlessly joined, coated with special varnish, and delivered turnkey with drains, EPS base, and heating device.

Model and mold construction for a high-speed train

Material |

Industry |

| EP paste, GRP | Rail vehicle construction |

Description:

The front of a train is not just its face. It must be aerodynamically designed and contains a lot of technology and details for coupling, attachment of windows including wipers, and much more. For the nose of an Asian high-speed train, we designed and manufactured a complete set of molds. The production conditions were defined by our customer, and the mold concept was designed in close consultation.

Delivery included:

Design of tools including parting lines and locking devices, CNC model making including lacquer finish, manufacturing of the multipart tool set in GRP including turning devices, subframes, etc., molds suitable for the use of polyester resins and a production temperature of 80°C

Masts and equipment carriers for various megayachts

Material |

Industry |

| CFRP/GRP sandwich | Shipbuilding |

Description:

For various yachts, we have manufactured equipment carriers and masts. Particularly important for our customers: the calculated weights were always adhered to and significantly undercut the weight of identical and comparable competitive products. The turnkey assembly was almost "plug'n'play" within just 3-4 days.

Delivery included:

Detailed engineering and construction, dimensioning against wind loads, natural frequencies, and dynamics in the wave, production conceptualization, CNC mold construction, manufacturing using the vacuum infusion process, assembly of threaded plates, empty cable ducts, lightning rods, etc., pre-finishing/priming, transport to the shipyard, assembly on the yacht.

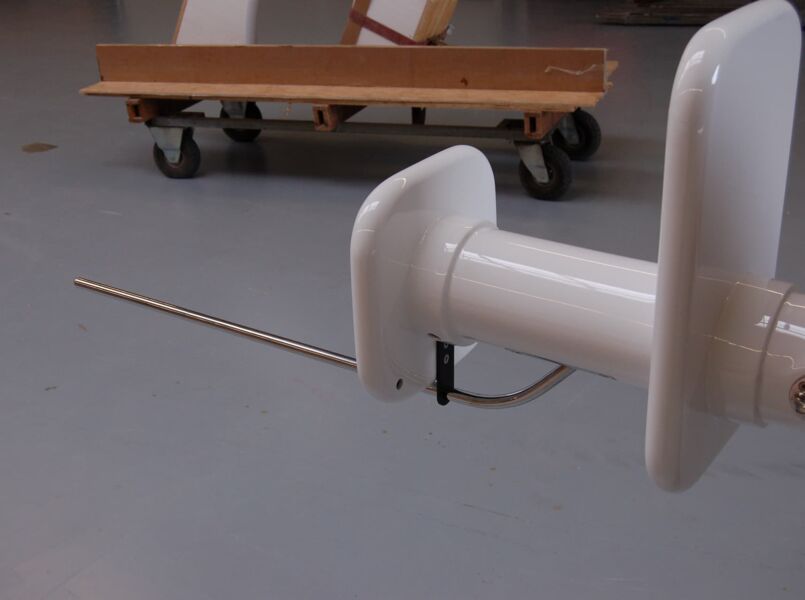

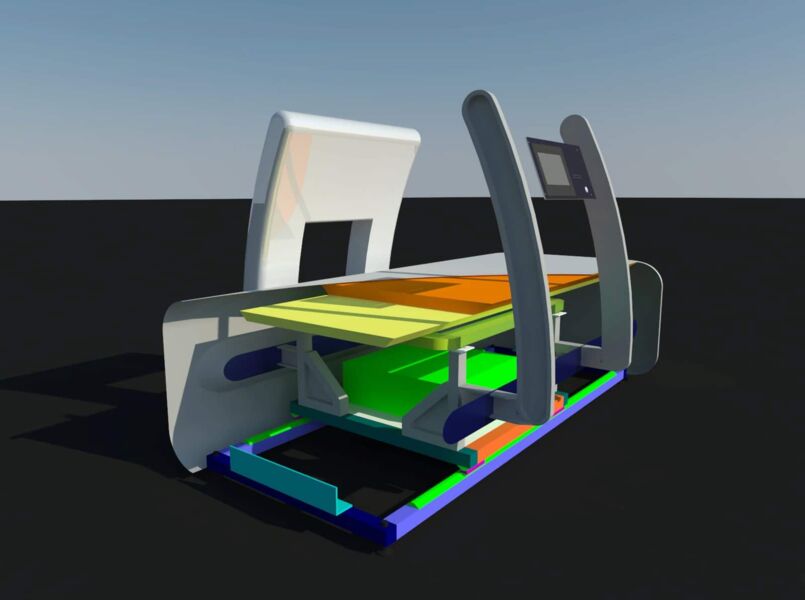

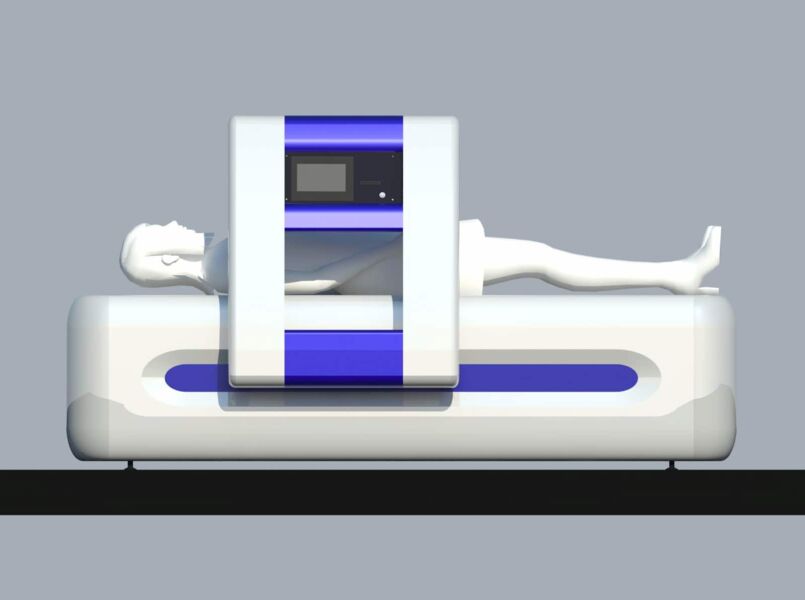

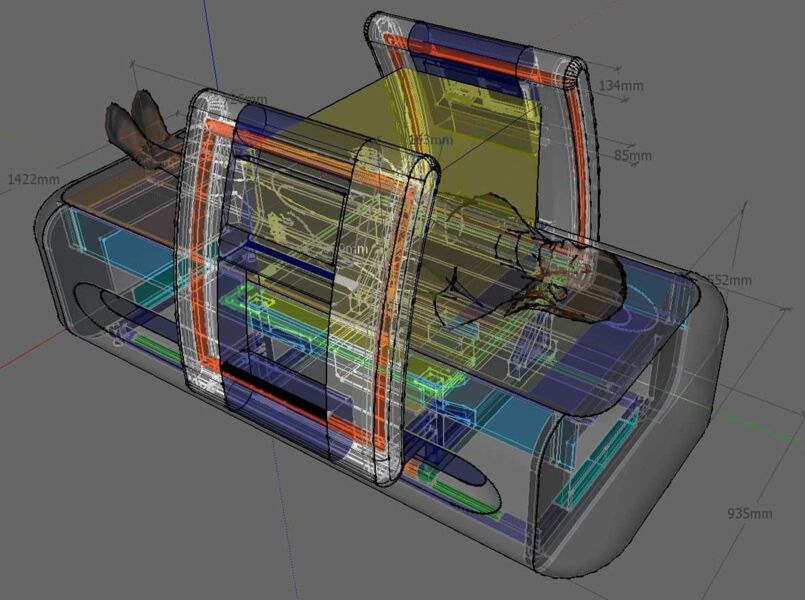

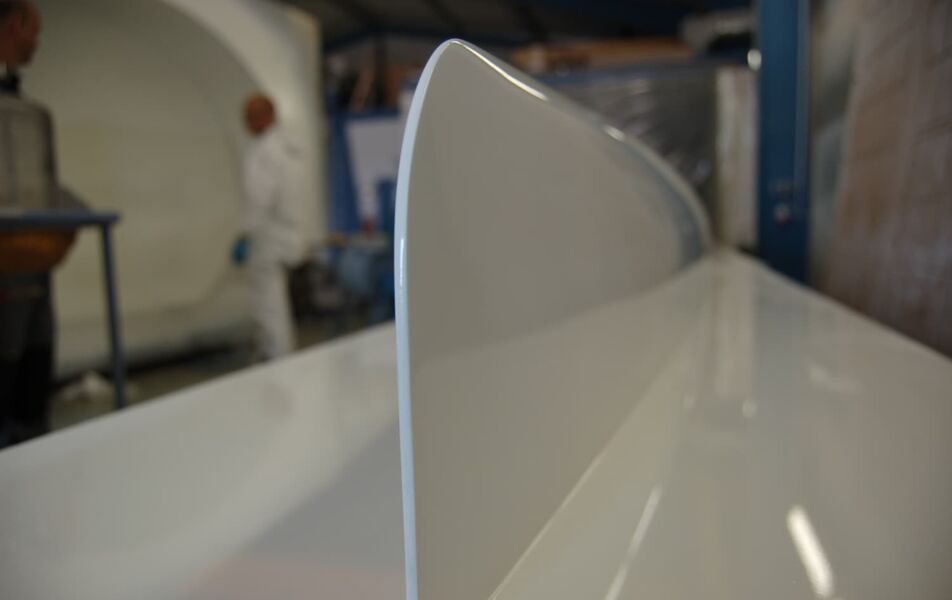

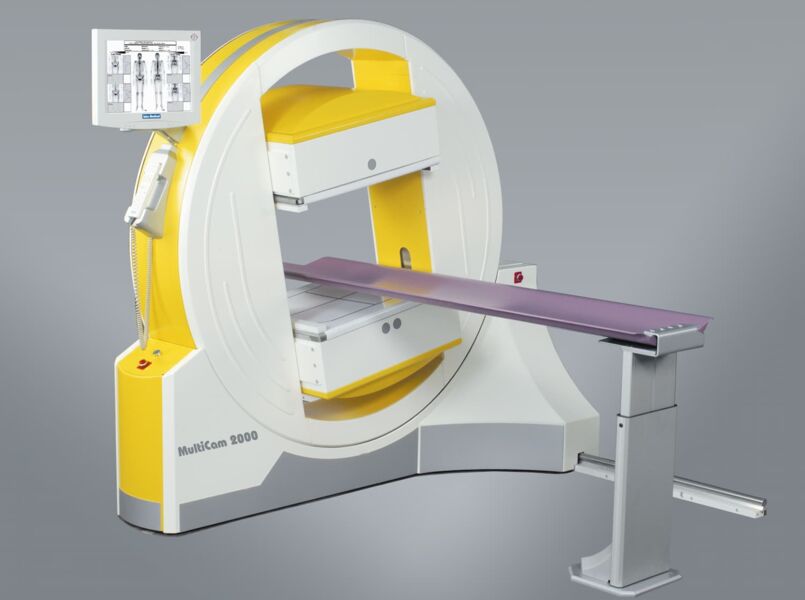

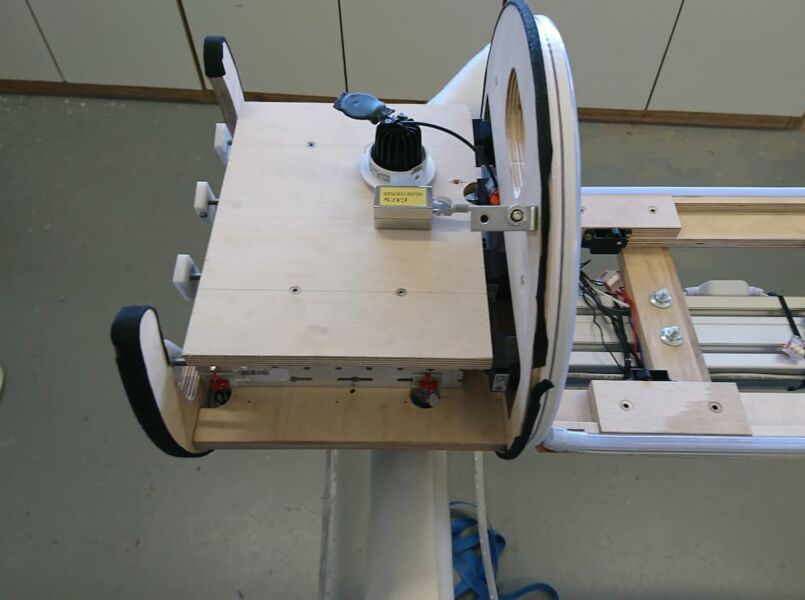

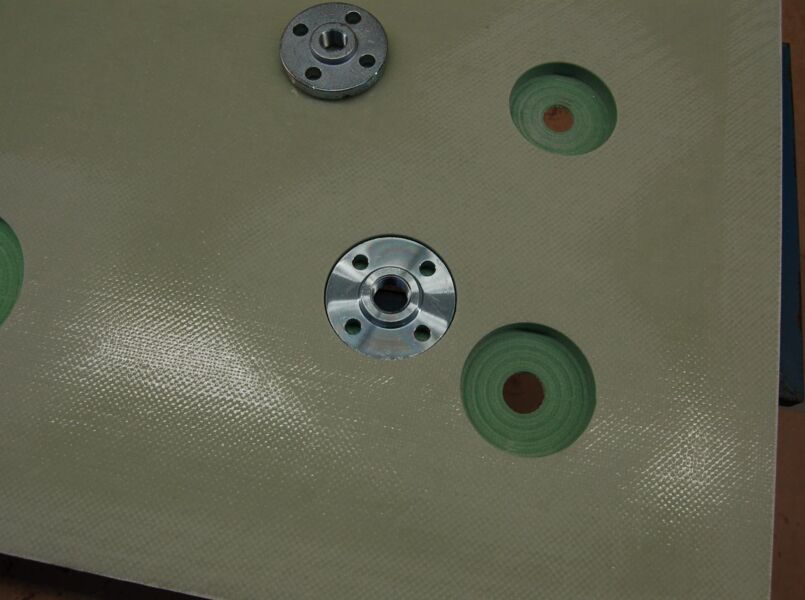

Development of three magnetic resonance therapy devices

Material |

Industry |

| GRP, Steel, PMMA | Medical technology |

Beschreibung:

With three new developments, our client, a medium-sized medical device manufacturer, underscores its innovative capability. We contributed the design, construction, and prototype building. In very close coordination with our client, it was essential to comply with the legal standards and regulations for medical devices. In addition, we also developed the corporate design, so that the new devices are recognizable as a product family. Finally, we supported the client by selecting and accompanying suitable suppliers in setting up mass production. The used, partially large and complex magnetic coils are encapsulated by us with a special resin.

Delivery included:

Design, visualization, construction, tool making, prototype construction, accompanying mass production, coil encapsulation

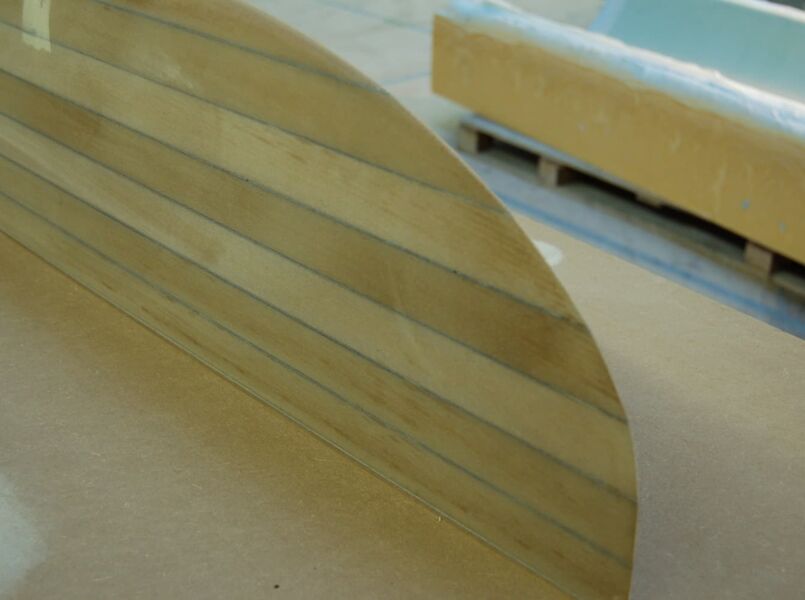

Model and mold construction for racing rowing boats

Material |

Industry |

| MDF/GRP/CFRP, high-gloss polished | Racing rowboat manufacturer |

Description:

Master models of various hulls, foredecks, and afterdecks of different types of racing rowboats, as well as the production of permanent molds (negative molds) from GRP or CFRP (heated).

Delivery included:

CAD data adjustment, CNC model making with high-gloss finish, negative mold from fiberglass-reinforced plastic (GRP) in sandwich construction, negative mold from carbon fiber-reinforced plastic (CFR) including electrical heating and temperature control.

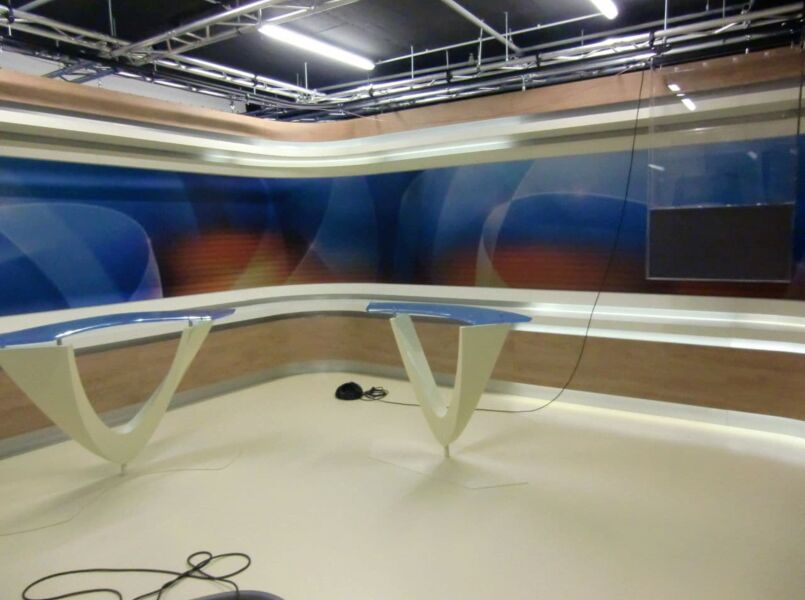

Moderation tables for five regional studios of SAT1

Material |

Industry |

| Painted hard foam and acrylic glass | Television/TV |

Description:

Moderation tables and interview tables were needed for the five regional studios of SAT1. The tables consist of an acrylic glass plate with a designer stand and a base.

Delivery included:

Data adjustment, construction (CAD), welded substructure, CNC model making of the individual table elements, surface finish according to customer specifications, adaptations of the acrylic table plates to the substructure, CNC manufactured packaging for safe transport to the various studios in Germany. We thank SAT.1 for the studio pictures that we are allowed to use.

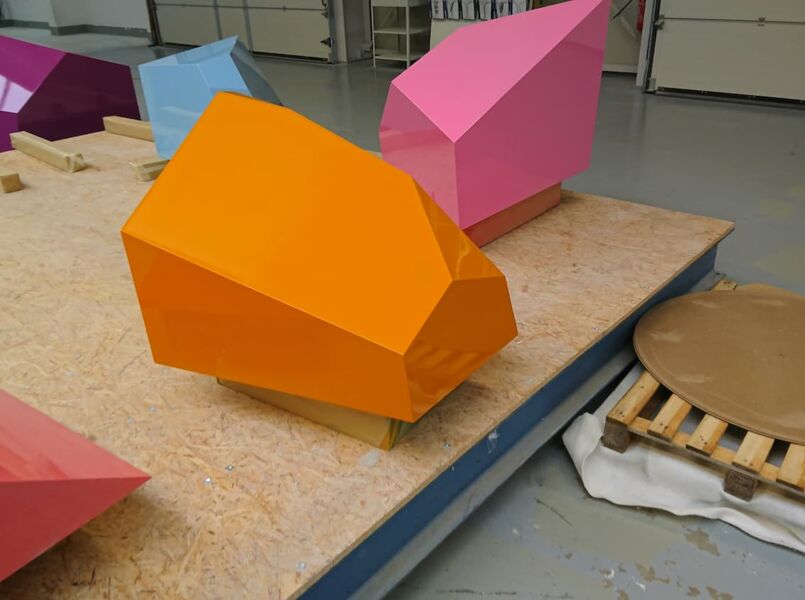

Stage design for the opera "Così fan tutte"

Material |

Industry / customer |

| High-gloss lacquered wood | Stage/Musical / Hamburg State Opera |

Description:

For the Mozart production "Così fan tutte" at the Hamburg State Opera, we developed central stage design elements. Our lacquering quality set a new standard for other opera houses as well.

Delivery included:

Consultation and conceptualization of the construction of the stage design elements, lacquering work.

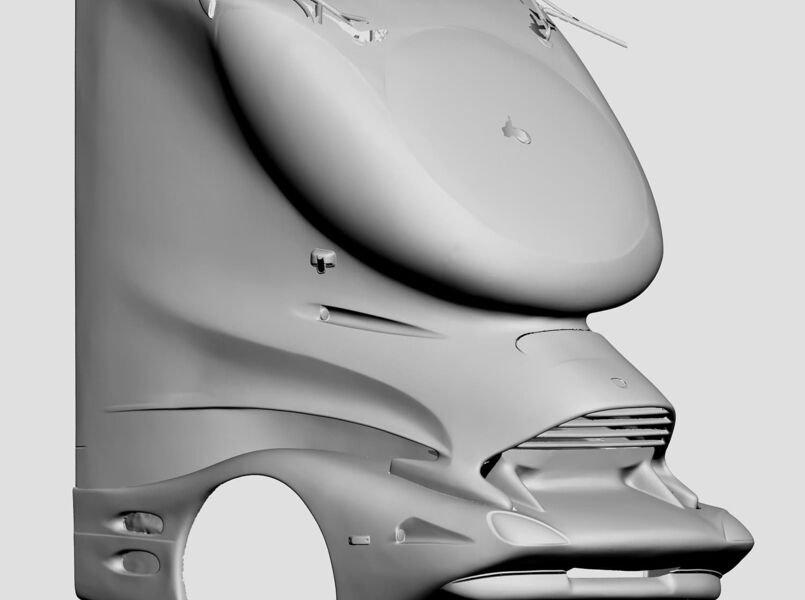

Reverse engineering for an exclusive luxury motorhome

Material |

Industry |

| Carbon fiber reinforced epoxy plastic (CFRP) | Vehicle construction |

Description:

The Colani design of this luxury motorhome looks not only unusual but also poses enormous challenges for vehicle construction. Based on a prototype, we completely digitally captured the cab using a 3D scanner and constructively revised the surfaces and established symmetry. In the next step, we digitally captured the Volvo chassis using photogrammetry, as no 3D data could be provided by the manufacturer.

Delivery included:

Technical project management, 3D scanning, 3D construction, mold construction, and production conceptualization.

Fully automatic water wall for the interior of a megayacht

Material |

Industry |

| Stainless steel, PVC-C | Shipbuilding/yacht building |

Description:

In the interior of a megayacht stands this nearly 5m high and 1m wide water wall. Through a nozzle specially developed by us for this application, a uniform film of water forms on a noble solid stone and flows over an overflow basin into the pool. We were responsible for the complete technical conception including construction, development of control technology, design of the water system, manufacturing of all stainless steel parts, assembly on board, and commissioning. The system operates fully automatically; circulating, cleaning, and changing the water as specified and is operated by a push button. For maintenance purposes, a touchscreen with clear text messages is available. In addition, the intensity of the water feature can be varied.

Delivery included:

Complete technical conception including construction, design of pumps and water pipes, development of the nozzle and control programs, manufacturing of all stainless steel parts, assembly on board, commissioning, and documentation.

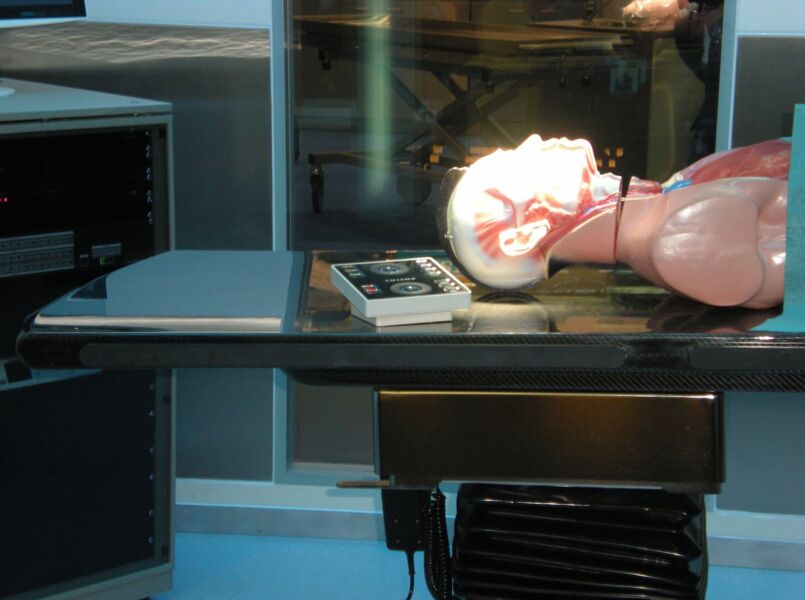

CFRP patient tables for use in X-ray machines

Material |

Industry |

| Carbon fiber reinforced epoxy plastic (CFRP) | Medical technology |

Description:

The top priority for X-ray device manufacturers is reducing radiation exposure for patients. However, when taking an X-ray, the X-ray tube must emit not only the radiation dose needed for the patient's imaging but also an additional dose that is absorbed by the table the patient lies on. This extra dose penetrates the patient, increasing their exposure. Therefore, it's crucial to use table tops that minimize radiation absorption. Simultaneously, the table top must be capable of supporting over 1,000 kg. We manufacture X-ray table tops for X-ray machines and PET scanners in small series.

Delivery included:

Component construction, design and dimensioning, mold construction, CNC model building, heated mold construction, small series production.

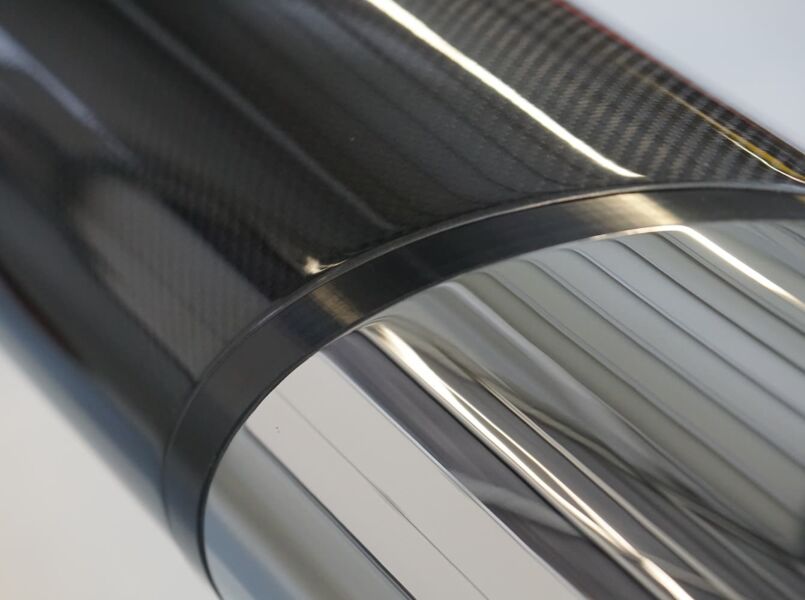

Flagpole in visible carbon look for a megayacht

Material |

Industry |

| Carbon fiber reinforced plastic (CFRP) | Shipbuilding/yacht building |

Description:

This detachable flagpole not only meets all requirements regarding wind loads and natural vibrations but also looks very high-quality with mirror high-gloss polished stainless steel and CFRP in visible carbon lacquer. Equipped with appropriate rope guides, empty cable ducts, and foundations for lamps, it also fulfills its original purpose, which should not be forgotten amidst all the design.

Delivery included:

Design, dimensioning and layout, CNC mold construction, manufacturing of CFRP laminates using the vacuum infusion process, lacquering, pre-assembly, fitting, and final assembly on board.

Interior design parts with a special look for an IAA show car

Material |

Industry |

| Fiberglass reinforced epoxy plastic (GRP) | Vehicle construction/automotive |

Description:

For an IAA show car/concept car, it was necessary to laminate existing aluminum trim strips with a special fiberglass. Due to this positive construction method, the surface quality had to be achieved through 10 clear coat layers with intermediate sanding. The gap dimensions and installation tolerances had to remain unchanged, of course.

Trade show construction for marine electronics manufacturer from CFRP visible carbon

Material |

Industry |

| Carbon fiber reinforced plastic (CFRP) | Marine electronics manufacturer/shipbuilding |

Description:

This manufacturer of marine electronic systems wanted to present its products at relevant trade fairs as if on a real ship's bridge, only more visually appealing in furniture construction made of real CFRP in visible carbon lacquer. The elements of the ship's bridge can be combined modularly, thus meeting the requirement to be individually assembled for each fair. The result not only thrilled our client but also the trade fair visitors. One visitor even wanted to equip the bridge of his ship in the style we delivered.

Delivery included:

Data adjustment, tool design (CAD), CNC mold construction/tool making, and production of CFRP visible carbon parts using the vacuum infusion process including trimming of the CFRP parts and cutouts using CNC milling, CNC milling of the sandwich cores, connection and fastening technology, and high-gloss surface finish.

Decorative grills, doors, and hatches for a very large megayacht

Material |

Industry |

| Fiberglass reinforced plastic (GRP) | Shipbuilding/yacht building |

Description:

12 assemblies, the longest extending to 14 meters, were required by our client, a renowned shipyard specializing in the construction of megayachts. Two of the so-called grills were delivered with hinges and hydraulics, and two more with appropriate hinges and locking systems, allowing the crew to open the elements. The client ordered a turnkey solution from us: from measurement to installation, all services were provided from a single source. The special aspect of this project was that the manufacturing process was entirely digital. Based on 3D data and measurements, all components were made from fiberglass reinforced plastic (GRP) in CNC milled molds. The pre-assembly took place in CNC milled jigs. After painting in our facility, the assembly on board was carried out using specially calculated and manufactured crane devices. The final result demonstrates the efficiency of our manufacturing process: more than 12 months passed between measurement and installation, during which we did not return to the board for inspection purposes. Despite the size of the assemblies, everything fit to the millimeter.

Delivery included:

Data adjustment, completely digital manufacturing process, 3D measurement, CNC mold construction, pre-assembly in CNC-milled jigs, painting, assembly on board including suitable crane devices.

Exterior/interior cladding elements for electric car

Material |

Industry |

| Painted PUR hard foam | Automotive/vehicle construction |

Description:

The key feature of this electric vehicle is its modularity. Based on a vehicle platform, various vehicle concepts are to be realized. Among other things, the owner can decide whether they need a 4-seater or a 2-seater with more cargo space. For the prototype, we directly milled the cladding parts for the interior and exterior and then applied the final paint. The trial assembly was also carried out by us.

Delivery included:

Data validation, CNC prototype construction, and surface finish.

Cream dispensing devices for cosmetics manufacturer

Material |

Industry |

| GRP/PMMA/aluminum | Consumer goods |

Description:

For the testing of various innovative sales concepts of a major cosmetics corporation, we created 3 different prototypes. The focus was on delivering hand and face creams more sustainably to the end consumer. The designed prototypes addressed 3 different sustainability concepts. Special importance was given to the integrated control and dosing technology. Contactless proximity sensors, sound output, light switching, and dosing mixing sliders required industrial control technology and meters of cable inside the devices.

Delivery included:

Technical conception, construction, control programming, building, and testing of three different prototypes.

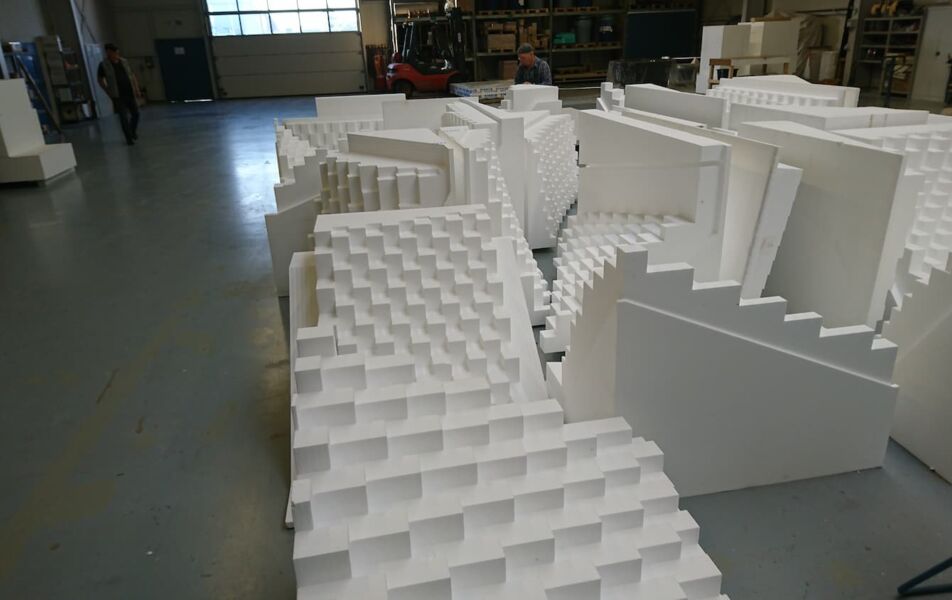

Formwork construction for the spectacular "Bricks" brick facade in Berlin

Material |

Industry |

| EPS/Styrofoam | Construction/architecture |

Description:

For the revitalization of the historic post office in Berlin, GRAFT Architects designed a very special courtyard passage. After several rejections regarding technical feasibility, GRAFT Architects found a partner in us for the implementation of this complex formwork construction.

Delivery included:

Technical conception, construction, support in the static layout and implementation of the multi-part formwork elements.

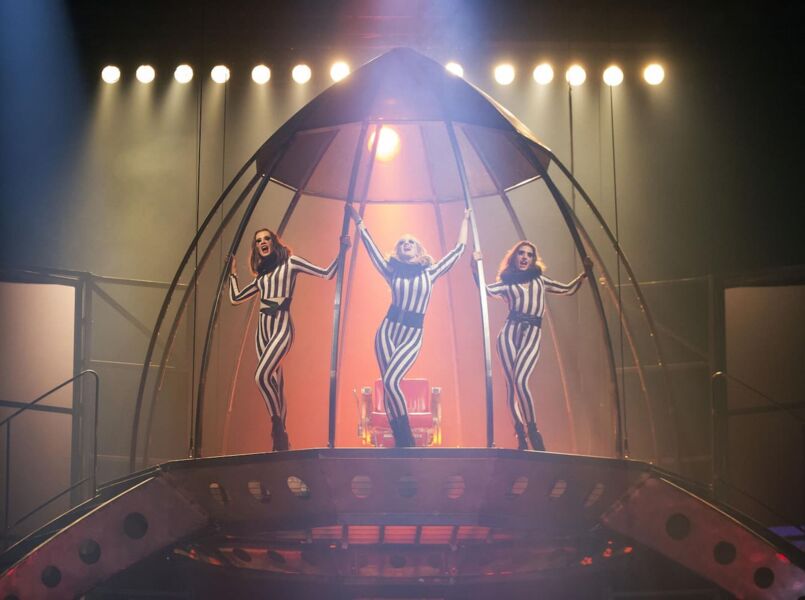

Stage design for David Bowie's musical Lazarus

Material |

Industry |

| Steel/Aluminum | Stage/Musical |

Description:

Shortly before his death, David Bowie wrote a poetically enigmatic musical. The Schauspielhaus Düsseldorf presented Lazarus as its German-language premiere. Central elements of the stage design were realized by us. We thank our client for generously providing the photographic material by photographer Lucie Jansch.

Delivery included:

Technical conception, construction, dimensioning, and implementation of the multipart steel and aluminum construction.

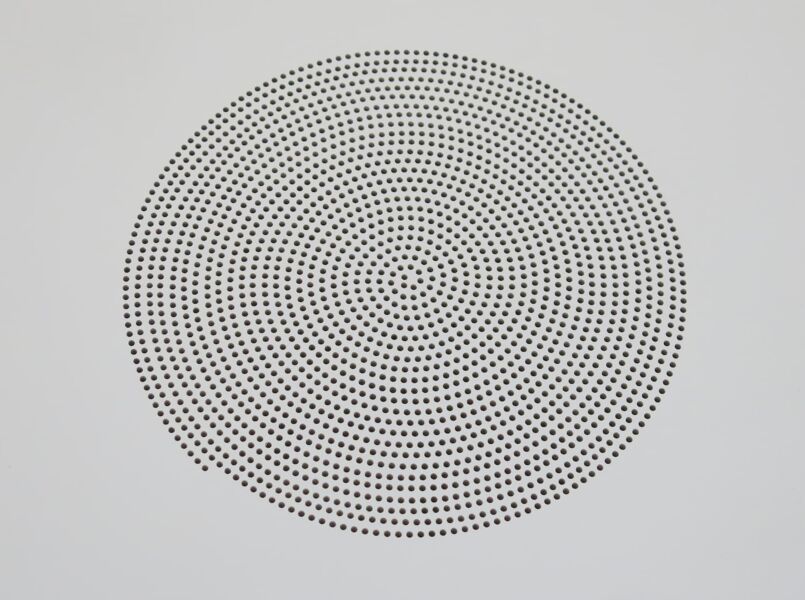

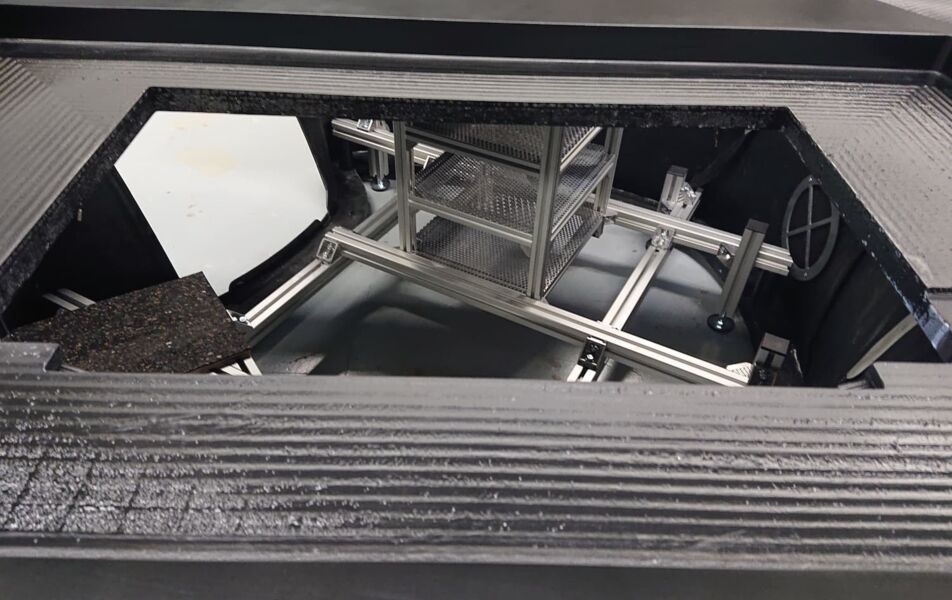

SAP media table in the Elbphilharmonie Hamburg

Material |

Industry |

| GRP | Media technology |

Description:

In the middle of the Plaza of the Elbphilharmonie, visitors of the Hamburg landmark can inform themselves about the spectacular building. The media table, to which we contributed, allows virtual tours through the Elbphilharmonie on three large touch monitors.

Delivery included:

Technical conception, construction, implementation, and installation support of the GRP media table.

Milling work for Steinway & Sons pianos

Material |

Industry / customer |

| Fine woods | Piano manufacturing / Steinway & Sons |

Description:

In our project with Steinway & Sons, we took on the challenge of perfecting wooden templates for piano models. Using state-of-the-art 3D scanning and CNC machining techniques, we transformed wood blanks into artistic pieces. This combination of craftsmanship tradition and high-tech processes demonstrates our ability to link tradition with innovation.

Delivery included:

3D scanning, construction, rough part drawings, CNC machining

Prototype construction for an innovative transportation solution

Material |

Industry |

| GRP | Research |

Description:

For a visionary underground transport project, we developed a prototype with the potential to revolutionarily change urban traffic. Our team tackled this complex task and created a solution that combines innovative transportation concepts with environmental protection.

Delivery included:

Construction, mold building, prototype construction.

Water tanks for a rail grinding vehicle

Material |

Industry |

| GRP | Rail vehicle construction |

Description:

Our latest project in rail vehicle construction involved the fabrication of eight GRP water tanks for a rail grinding vehicle in Brazil. These tanks are specially designed for the high requirements of the vehicle, demonstrating our expertise in manufacturing customized industrial products.

Delivery included:

Construction, dimensioning/design, manufacturing including connections, threaded inserts, and leak tests

Lost master model for bronze casting

Material |

Industry |

| EPS/Styrofoam | Art |

Description:

For an impressive art installation in Berlin, we manufactured scale EPS models that served as the basis for artistic bronze statues. This project vividly illustrates how we combine artistic creativity with precise technical implementation.

Delivery included:

3D scan, scaling/construction, CNC machining

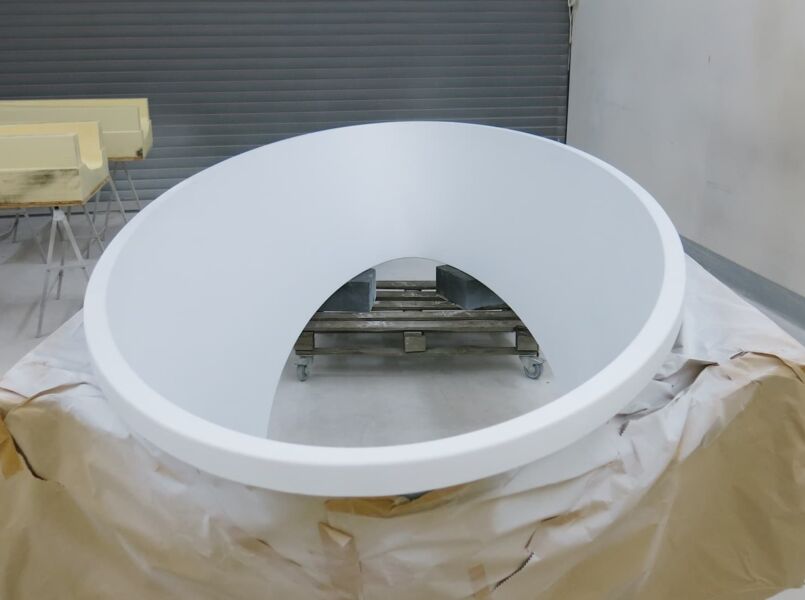

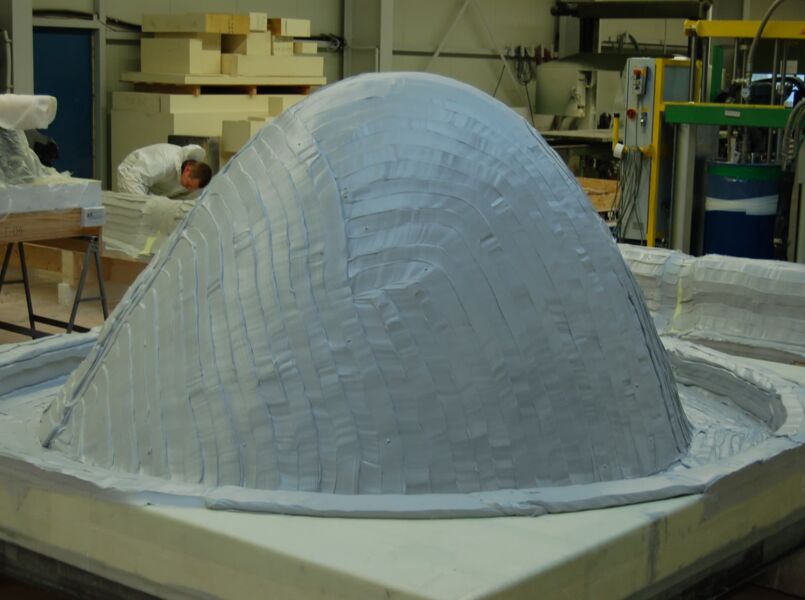

Mold construction for paraboloid

Material |

Industry |

| Paste | Aviation |

Description:

In the aviation sector, we have excelled in the development and manufacturing of vacuum-tight molds for paraboloids. This challenging task required utmost precision and technical understanding to meet the specific demands of the aerospace industry. Our commitment and ability to successfully tackle complex challenges are impressively underscored by this project.

Delivery included:

Construction, CNC mold making, surface finish

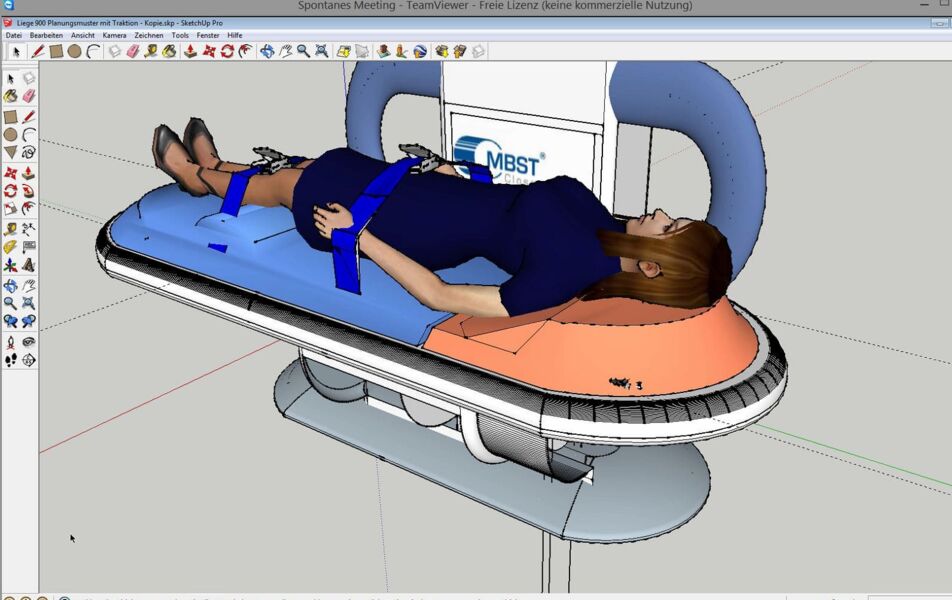

Prototype of a medical therapy device

Material |

Industry |

| GRP/Plastics/Aluminum, Steel, etc. | Medical technology |

Description:

In an ambitious project with a leading German medical technology company, we played a significant role from the design phase to the completion of the prototype of an innovative therapy device. Our extensive experience and technical expertise in the medical technology sector were fully utilized. The project demonstrates our capability to develop and implement highly complex medical devices in practice.

Delivery included:

Design, construction, documentation for certification, mold building, prototype construction.